Felted LED plate

by andreamiller

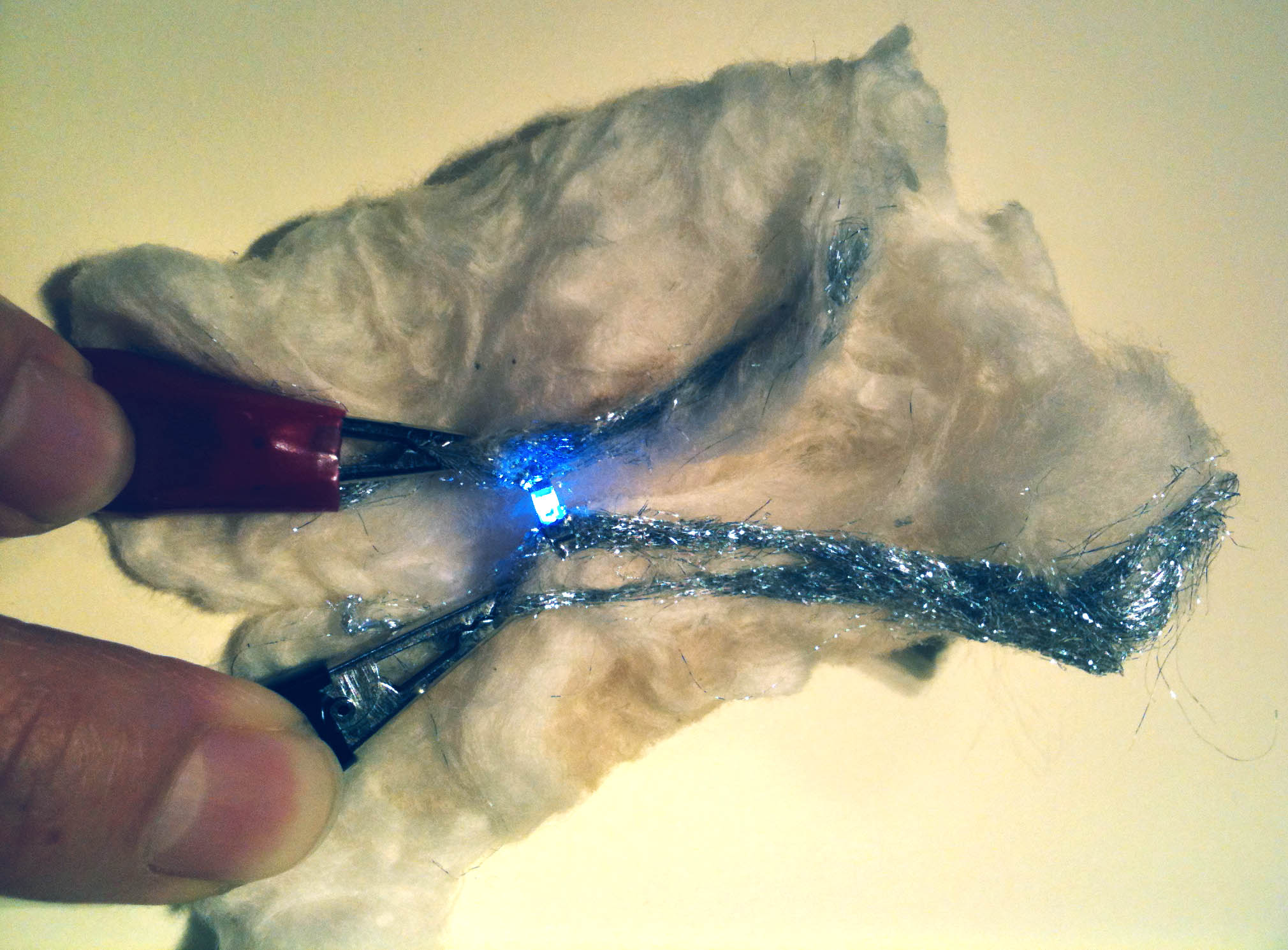

For the nonwoven textile project, I tested felting wool roving with aluminum wool as conductive material. In this quick test, I soldered a small LED to a crimp-beaded aluminum wool. It seems to light up and work! I liked the fact that everything can be felted into one material/surface; no need for stitching conductive thread, etc.

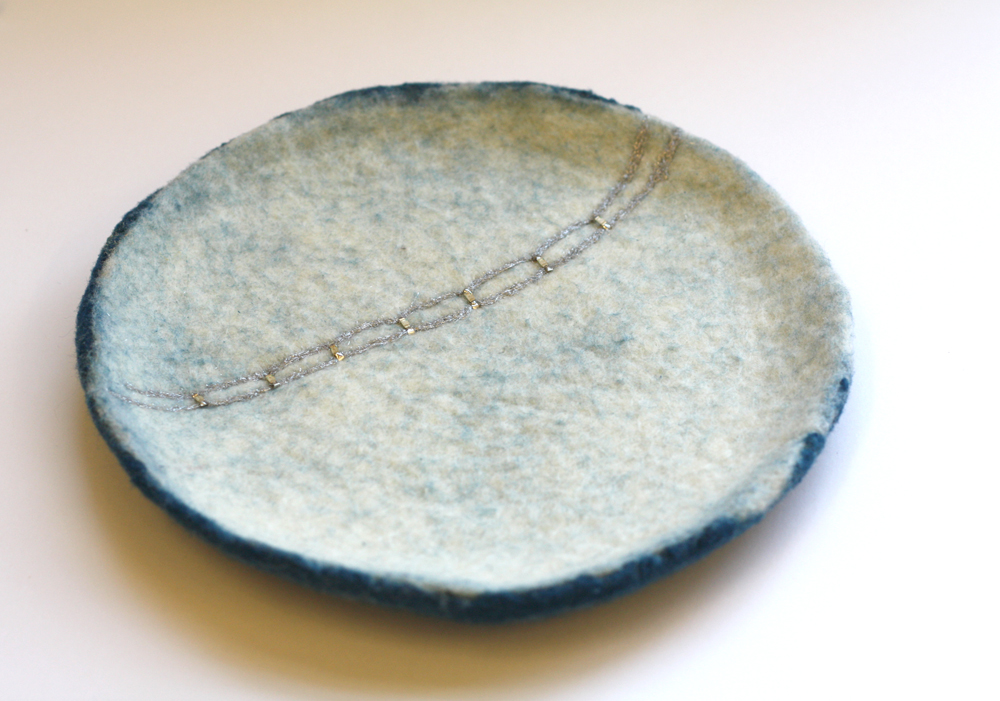

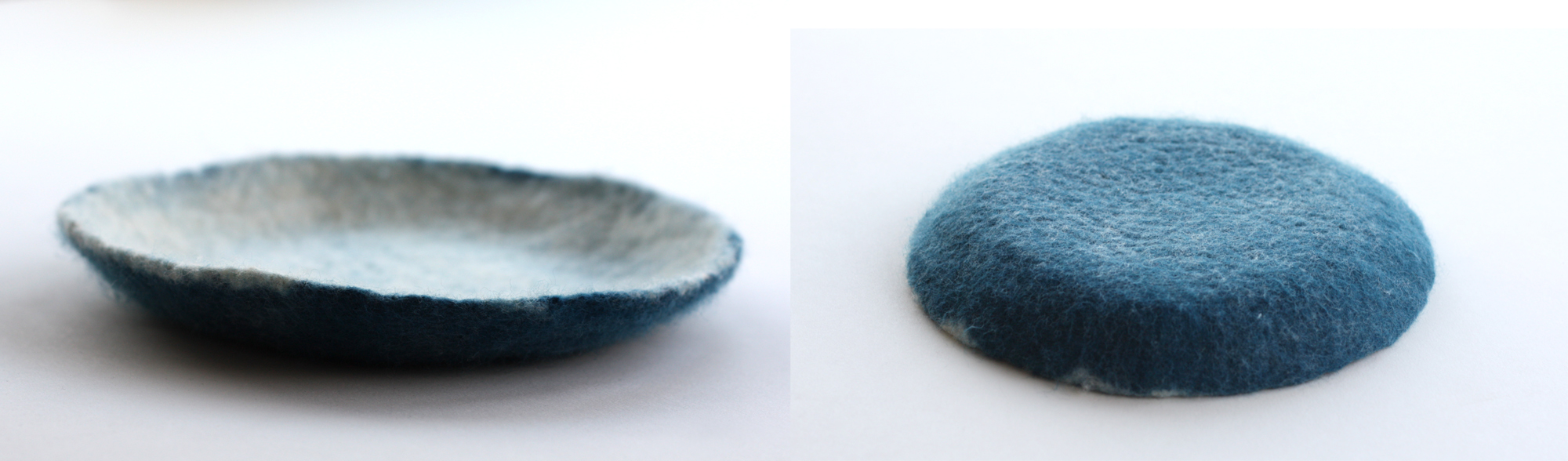

I decided to wet felt a small plate and needle felt aluminum wool into two strands where I can attach series of LEDs. Pictures below show the felting process, where I layered two different colors of wool roving and used a bowl as a mold to felt the plate shape.

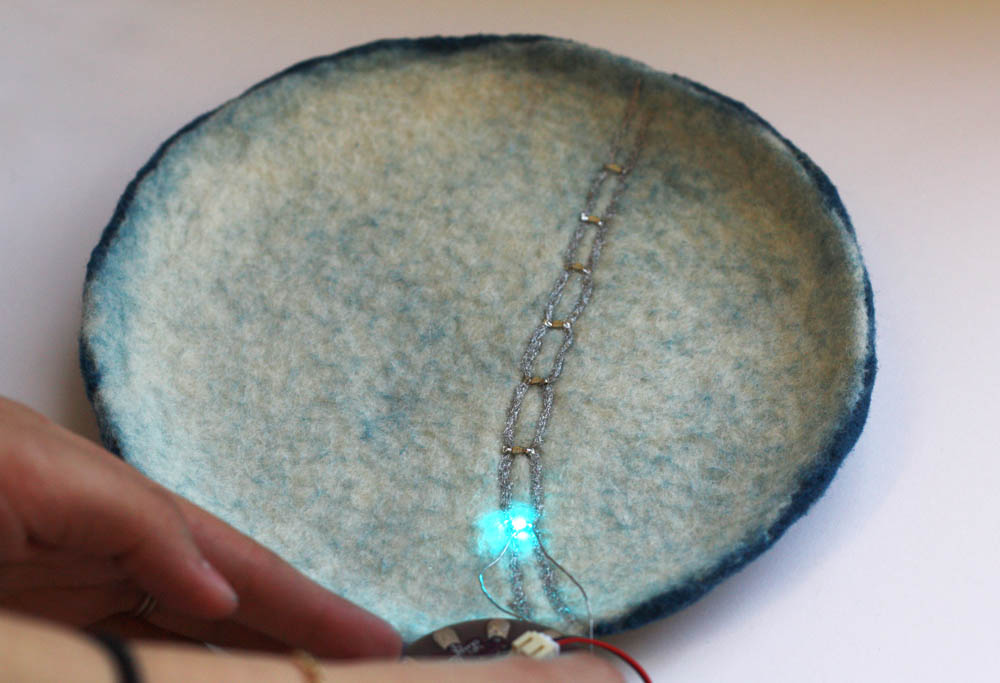

After the bowl is felted, I needle felted two rows of aluminum wool. Since the aluminum wool doesn’t solder well, I added crimp beads where I wanted to attach LEDs to. Making sure that the LEDs are all aligned in the right direction, I soldered the LEDs to the crimp beads. And.. it should light up with the lilypad battery! Hmmm…. although individual LEDs light up when lilypad is connected individually, the row of LEDs do not light up all together. I’m guessing the aluminum wool is not conductive enough, or the wool fibers are shorting the circuit. Time to debug!

After the bowl is felted, I needle felted two rows of aluminum wool. Since the aluminum wool doesn’t solder well, I added crimp beads where I wanted to attach LEDs to. Making sure that the LEDs are all aligned in the right direction, I soldered the LEDs to the crimp beads. And.. it should light up with the lilypad battery! Hmmm…. although individual LEDs light up when lilypad is connected individually, the row of LEDs do not light up all together. I’m guessing the aluminum wool is not conductive enough, or the wool fibers are shorting the circuit. Time to debug!