Soft FSR Sensor

by trich

VIEW THE VIDEO HERE: https://vimeo.com/37611424

For this project, I reverse engineered a simple traditional FSR resistive sensor in order to make it larger and textile based. The FSR sensors that are commercially made are very similar to the versions we were making in class, with a few slight variations. They essentially consist of two interlaced but separate circuit traces, a spacer and a semi conductive substrate backing- similar to the velostat we used.

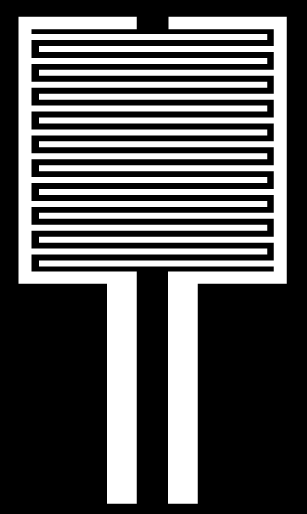

I generated a pattern for my traces in illustrator and printed it out.

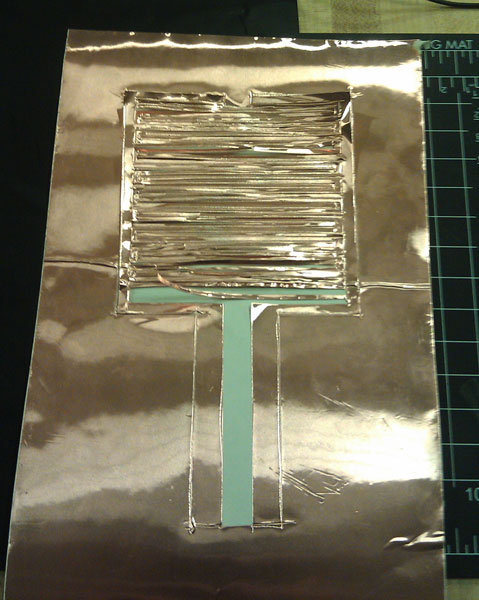

Using a ballpoint pen, I traced my pattern into a piece of copper tape.

I then hand cut the traces out of the tape with a metal ruler and an exacto knife (no vinyl cutter needed!) As a result, this entire project consists of materials and processes that can be performed at home without any special equipment.

I pulled up the copper from its backing using a large piece of masking tape

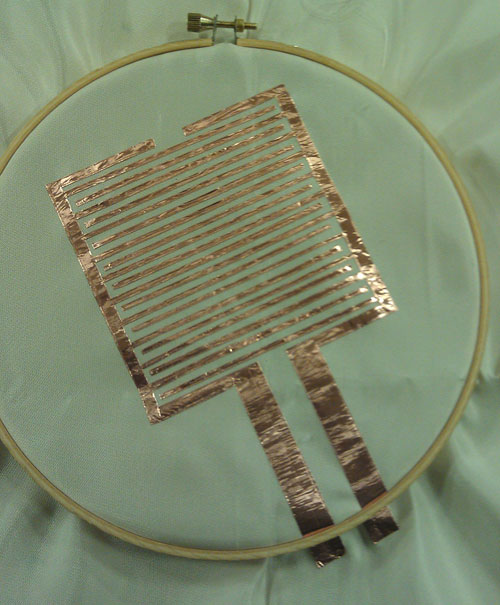

and then easily transfered it to a piece of light fabric which I had previously stretched across an embroidery hoop and weeded out any of the unnecessary copper with a pair of tweezers.

I cut a fabric spacer out of felt and sewed it around the copper pattern to separate the copper from the velostat.

I then sewed a square of velostat on top and proceeded to test the sensor. I pulled the input pin low by connecting it to ground with a 10k resistor, and attached the other trace to power. With the spacer, I got a pretty good range of values from the sensor, surprisingly comparable to a commercially made one. When no pressure was generated the sensor read 0, and ranged up to 1023 in the analog read, with varying levels of pressure. The readings were also highly consistent.

I cut a basic pattern to enclose the sensor, that could be padded with additional material to make a more squeezable interface.

I stuffed the sensor inside, along with some general pillow stuffing and a piece of felt separating it from the surface of the cover. This will prevent any traces that run along the surface of the cushion from interfering with the sensor.

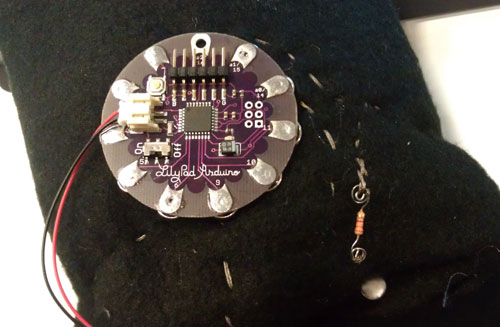

I rigged the sensor to a lilypad with conductive thread, and hooked up an led on the front of the cushion to act as an output mechanism. I also adjusted the code to give the sensor a bigger buffer when translating the values to the led output. (Because the cushion is stuffed, the sensor is already partially pressed.)

It works really well!